Slitting Rewinding job work

Slitting Rewinding job work Specification

- Voltage

- 220/ 415 Volt(v)

- Noise Level

- low db

- Cooling System

- Air Cooling

- Features

- Heavy Duty

- Machine Type

- rewinding machine

- Frequency

- 50/6 Hetrz (Hz)

- Frame Type

- Metal Frame

- Product Type

- Construction Equipment

- Technology

- CNC

- Power Source

- Electricity

- Operating Type

- Automatic

- Surface Treatment

- Coated

- Color

- Silver

- Warranty

- 1 year

- Usage & Applications

- Industrial

Slitting Rewinding job work Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Month

- Delivery Time

- 7 Days

About Slitting Rewinding job work

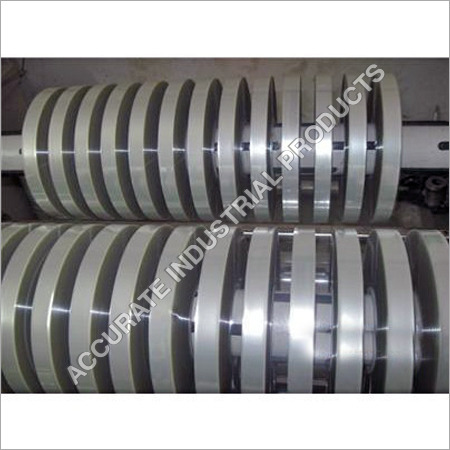

Slitting Rewinding Machine

Backed by the well equipped infrastructural facilities and experienced personnel, our company has emerged as one of the well established manufacturers and exporters of Slitting & Rewinding. The rewinding machine is manufactured by using finest quality materials as per set international standards under the strict guidance of skilled professionals. This machine is acknowledged for its features like hassle free operation, longer service life and optimum performance. The Slitting & Rewinding is widely used in paper industry.

Further Details:

We are also known for offering slitting & rewinding services to the clients. These services are executed by a team of deft experts holding immense expertise in their respective fields. Our professionals make use of advanced tools and equipment to render these services. We offer job work of the following:

- Polyester Film

- B.O.P.P Film

- Insulation press paper & Kraft paper

- Laminated material

- Foil & Film & Label

Advanced Technology for Improved Efficiency

This slitting rewinding machine employs CNC technology, enabling automated processes that enhance efficiency and consistency. Operators benefit from precise, repeatable slit results, reducing errors and increasing throughput for industrial tasks. The integration of automated controls simplifies operation while maintaining high safety standards.

Durable Design and Easy Operation

Crafted with a sturdy metal frame and finished in a silver color, the machine offers longevity for demanding environments. The air cooling system prevents overheating during extended use, and the low noise level supports a comfortable workplace. Its automatic operation minimizes manual intervention and boosts productivity.

FAQs of Slitting Rewinding job work:

Q: How does the slitting rewinding process work on this machine?

A: The automatic rewinding machine uses CNC technology to slit large rolls of material into narrower widths. It then rewinds each slit section onto separate cores, resulting in neatly wound and evenly cut rolls ready for industrial use.Q: What are the key benefits of the surface-treated, coated rewinding machine?

A: With its coated surface treatment, the machine offers better durability and corrosion resistance, ensuring a longer service life. The precise CNC controls and heavy-duty build provide reliable, high-quality job outcomes with minimal maintenance.Q: When is it ideal to use this slitting rewinding service?

A: This service is perfect for industries that require precise, efficient slitting and rewinding, such as packaging, printing, textiles, or label manufacturing, especially when handling bulk material rolls that demand consistency and speed.Q: Where can this machine be installed?

A: The machine is suitable for installation in industrial plants across India, thanks to its compatibility with 220V/415V power supplies and air cooling system. Its robust metal frame ensures stability, making it practical for various work environments.Q: What makes the operation of this slitting rewinding machine user-friendly?

A: The machine features automatic controls, a low noise level, and a simple user interface, enabling operators to manage the process efficiently and safely with minimal training input.Q: How does the air cooling system support continuous operation?

A: The integrated air cooling mechanism dissipates heat generated during operation, allowing the machine to run efficiently for extended periods without risk of overheating, thus reducing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+